Best Practices for Inventory Management in Material Handling

Understanding Inventory Management

Inventory management is the cornerstone of efficient material handling operations. It involves overseeing the flow of goods from suppliers to warehouses and eventually to customers. This process ensures that the right products are available in the right quantities at the right time, thereby minimizing stockouts and excess inventory.

Definition and Importance

Inventory management refers to the strategic control and supervision of the ordering, storage, and usage of goods. Its significance lies in optimizing cash flow, maximizing warehouse space utilization, and meeting customer demands promptly.

Types of Inventory

There are various types of inventory, including raw materials, work-in-progress, and finished goods. Each type requires different management approaches to ensure smooth operations.

Challenges in Material Handling

Inefficient Processes

One of the primary challenges in material handling is inefficient processes. This can lead to delays in order fulfillment, increased lead times, and higher operating costs.

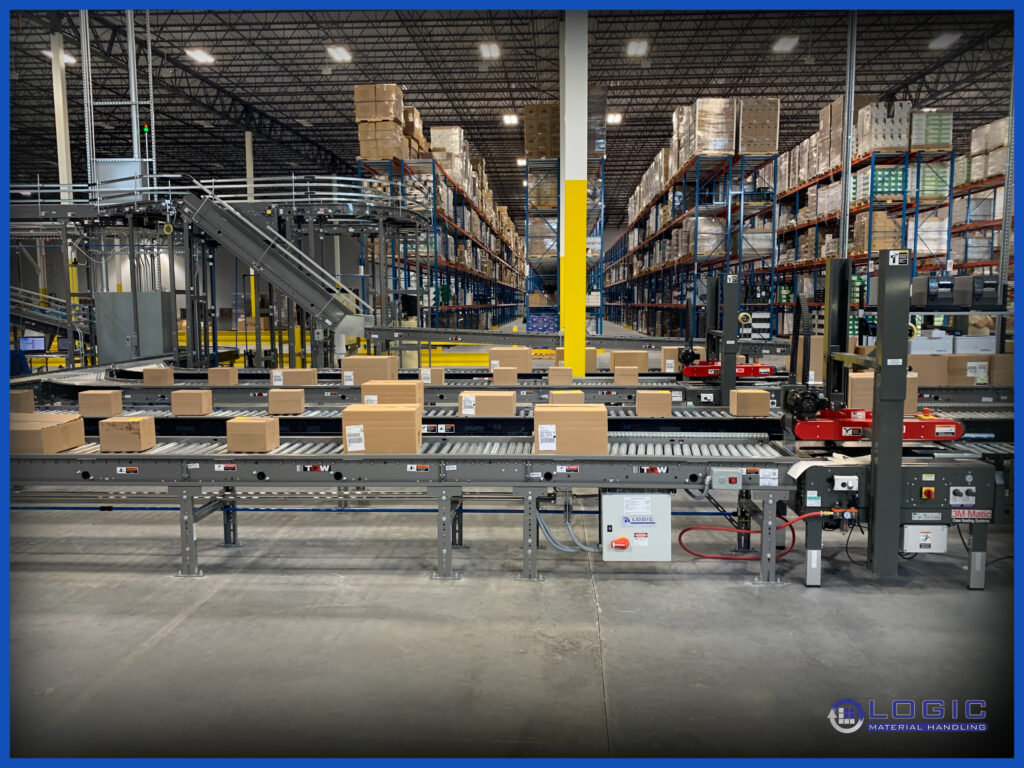

Lack of Automation

Many material handling facilities still rely on manual processes, which are prone to errors and inefficiencies. Automation solutions such as conveyor systems and robotic picking can streamline operations and improve accuracy.

Inventory Tracking Issues

Poor inventory tracking can result in stockouts or overstocking, leading to lost sales and increased carrying costs. Implementing robust tracking systems, such as barcode scanners or RFID technology, can address these issues.

Best Practices

Utilizing Inventory Management Software

Inventory management software provides real-time visibility into inventory levels, demand forecasts, and supplier performance. It streamlines order processing, reduces paperwork, and enhances accuracy.

Implementing RFID Technology

RFID technology enables automatic identification and tracking of inventory items using radio frequency signals. It eliminates the need for manual scanning and provides accurate, up-to-date information on inventory status.

Embracing Lean Principles

Lean inventory management focuses on minimizing waste and maximizing efficiency. By implementing lean principles such as just-in-time production and kanban systems, businesses can reduce excess inventory and improve responsiveness to customer demand.

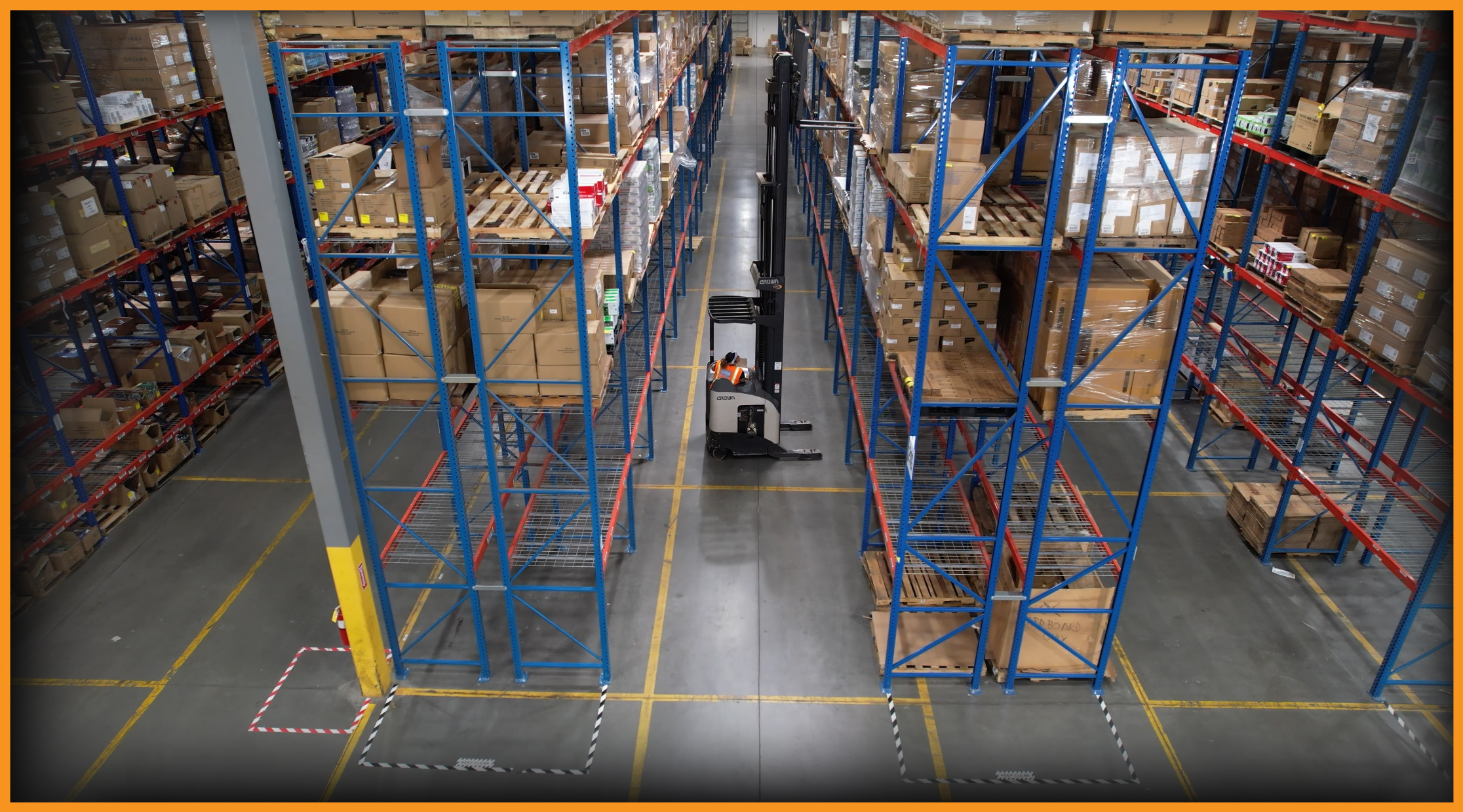

Optimizing Warehouse Layout

A well-organized warehouse layout facilitates efficient material flow and minimizes picking time. By arranging storage locations based on product demand and implementing clear signage, businesses can enhance productivity and reduce errors.

Adopting Just-in-Time Inventory Systems

Just-in-time inventory systems involve replenishing stock only when needed, thereby reducing carrying costs and minimizing waste. By synchronizing production with customer demand, businesses can improve cash flow and responsiveness.

Conducting Regular Audits

Regular audits help identify discrepancies between physical inventory and recorded inventory levels. By reconciling these differences promptly, businesses can prevent stockouts, shrinkage, and other inventory-related issues.

Benefits of Effective Inventory Management

Increased Efficiency and Productivity

Effective inventory management leads to smoother operations, shorter lead times, and higher productivity levels. By optimizing inventory levels and streamlining processes, businesses can fulfill orders more quickly and efficiently.

Cost Reduction

Optimizing inventory levels and minimizing waste can significantly reduce carrying costs and overhead expenses. By eliminating excess inventory, businesses can free up capital for other investments and improve their bottom line.

Enhanced Customer Satisfaction

Timely order fulfillment and accurate inventory information contribute to improved customer satisfaction. By ensuring that products are available when customers need them, businesses can build trust and loyalty among their customer base.

Conclusion

In conclusion, effective inventory management is crucial for optimizing material handling operations. By understanding the importance of inventory management, addressing common challenges, and implementing best practices, businesses can improve efficiency, reduce costs, and enhance customer satisfaction.

FAQs

Q: What is the role of inventory management software?

Inventory management software provides real-time visibility into inventory levels, demand forecasts, and supplier performance. It streamlines order processing, reduces paperwork, and enhances accuracy.

Q: How does RFID technology improve inventory management?

RFID technology enables automatic identification and tracking of inventory items using radio frequency signals. It eliminates the need for manual scanning and provides accurate, up-to-date information on inventory status.

Q: What are the key principles of lean inventory management?

The key principles of lean inventory management include minimizing waste, maximizing efficiency, and synchronizing production with customer demand. Techniques such as just-in-time production and kanban systems are commonly used to achieve these goals.

Q: How can businesses optimize warehouse layout for better inventory management?

Businesses can optimize warehouse layout by arranging storage locations based on product demand, implementing clear signage, and minimizing travel distances for workers. This facilitates efficient material flow and reduces picking time.

Q: What are the main benefits of implementing just-in-time inventory systems?

Implementing just-in-time inventory systems can reduce carrying costs, minimize waste, and improve responsiveness to customer demand. By replenishing stock only when needed, businesses can optimize inventory levels and free up capital for other investments.