HOW TO CHOOSE THE RIGHT CONVEYOR SYSTEM/BELT?

Are you less than satisfied with the results of your current order fulfillment system?

Slow pick rates and incorrect shipments limit your ability to provide the best possible service to your customers, which ultimately impacts your company’s bottom line.

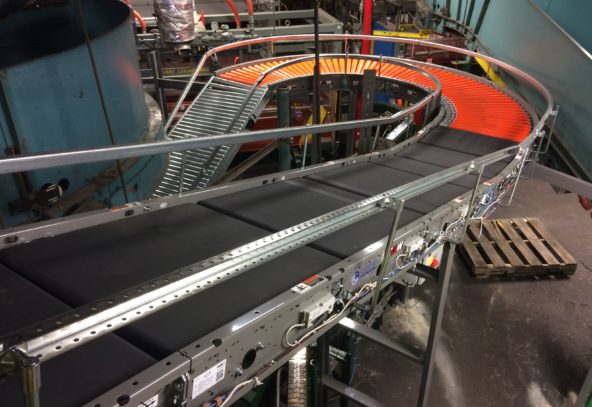

Logic Material Handling, Inc. is a provider of turnkey material handling systems that offer a cost-effective solution. We can design and install an automated conveyor system that will dramatically increase the efficiency of your warehousing operation.

![TGW Ermanco Conveyor Systems in [city]](https://logicmaterialhandling.com/wp-content/uploads/2016/02/IMG_7027-1.jpg)