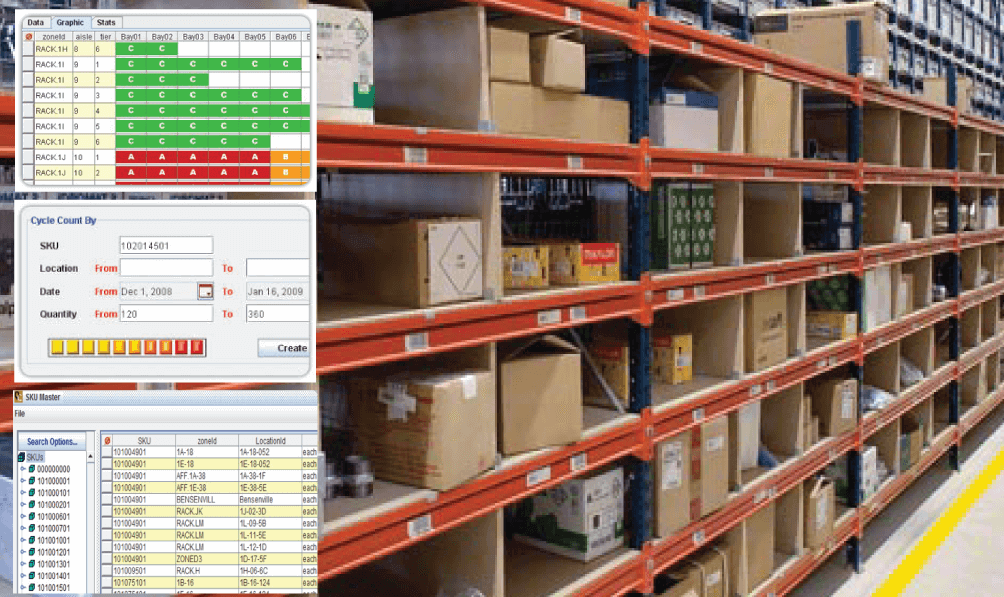

A Warehouse Controls System (WCS) is a

software application which directs real-time activities within your warehousing, manufacturing, or distribution facility. The WCS accesses information from your WMS or host software and directs activities based upon a set of custom business rules designed for your operation. This system gives you full visibility of your operation’s functions (picking, packing, conveyor routing, shipping, ect) as they occur and is web enabled to allow access to information off site. This system ties into your

material handling technologies including AS/RS, Vertical Lift Modules, Conveyor System, RF Scanners to control the processes of these automated systems. The WCS directs order management, inventory levels, shipping activities, and provides statistic reporting on all of these processes. Perfect for a company looking to transform their operation from basic paper based processes into a highly efficient system designed around their business’s needs.